As technological advancements continue to reshape the landscape of industrial processes, the threats to manufacturing facilities have evolved as well. From physical theft and sabotage to cyberattacks and supply chain disruptions, manufacturing plants face multifaceted challenges that demand a proactive and comprehensive approach to security.

In the past, manufacturing security primarily involved physical measures such as surveillance cameras, access control systems, and perimeter fencing. While these measures remain essential, the scope of security considerations has expanded dramatically. The advent of automation, data-driven processes, and interconnected machinery has introduced new vulnerabilities.

One of the most pressing concerns in contemporary manufacturing is the rise of cyber threats. With industrial control systems (ICS) and operational technology (OT) becoming increasingly networked, manufacturing plants are exposed to cyberattacks that can disrupt operations, compromise sensitive data, and even endanger employee safety.

In recent years, high-profile incidents, including ransomware attacks and data breaches, have highlighted the urgent need for robust cybersecurity measures within manufacturing facilities.

While cyber threats are a growing concern, the importance of physical security cannot be overstated. Manufacturing plants still face risks related to theft, vandalism, and industrial espionage.

Ensuring the physical safety of employees and assets remains a top priority. Additionally, global supply chain disruptions and geopolitical tensions have reinforced the importance of securing the entire manufacturing ecosystem, from raw material sources to distribution networks.

Balancing Security and Operational Efficiency

Any disruption to operations, regardless of size, can have dire financial consequences for the manufacturing company’s bottom line and the supply chain at large. Moreover, manufacturing invests millions of dollars in machinery, raw materials, staffing, and technology. Therefore, decision-makers need to understand all the risks that can affect operations, assets, finances, and brand reputation.

Manufacturers must find a balance between security measures and operational efficiency. Excessive security protocols can impede productivity, hinder innovation, and increase costs. That’s why effective security strategies should be integrated seamlessly into the manufacturing process, enhancing safety without sacrificing efficiency.

7 Ways to Enhance Security in Manufacturing Facilities

Protecting a manufacturing facility requires a well-thought-out multilayered security program. Here are the top ways to help enhance manufacturing facility security become proactive and work more effectively than the traditional reactive security of the past. Doing these things will help minimize security risks and avoid contributing to the supply chain crisis.

1. Hire a security consultant

Physical security is an area that requires security professionals. To ensure the manufacturing facility’s security is efficient and effective, bring in a security consultant with experience securing manufacturing facilities. Every industry, and even two manufacturing facilities, have different security requirements and best practices. That’s why it’s crucial to find a security professional with experience in manufacturing.

The manufacturing facility security consultant can customize and optimize security based on an individual manufacturing facility’s budget, needs, and requirements. In the search for a vendor, check for credentials such as Certified Security Consultant (CSC), Certified Protection Professional, or Physical Security Professional.

2. Conduct a security risk assessment

The security consultant can conduct a security risk assessment. They will review what security measures are in place at the manufacturing facility and find potential vulnerabilities. The assessment also involves an analysis of crime reports to understand what kinds of crimes occur around the manufacturing facility’s neighborhood.

The security consultant may use a reporting tool like the National Incident-Based Reporting System (NIBRS) from the FBI. It contains interactive maps using data from local law enforcement agencies. The system allows people to search for a geographic location to view the crime data for specific neighborhoods. NIBRS highlights the crime rate and the types of crime reported to the local law enforcement agency.

The security professional may also look at the weather patterns and history in the area for other risks. Knowing the risks of nature-made disasters helps companies be better prepared.

A security risk assessment requires regular review and updating. Physical security and technologies evolve quickly. Conducting an annual security assessment involves assessing the security program’s performance and identifying areas for improvement.

3. Document and maintain a security plan

The next step after the risk assessment is the creation of a security plan. An assessment is a snapshot of the security as it stands today and identifies vulnerabilities. A security plan is an action plan to close the vulnerabilities. It may have a layout of the manufacturing facility along with perimeter security measures to implement.

It documents the security requirements for the manufacturing facility and its exterior areas including landscaping and parking. The plan needs to mention and address providing security training for workers on a regular basis. All it takes is one person’s mistake to create a major security hole. This is why training and layered security are important.

The facility may not have a security professional. That’s why it’s key to identify the employee who will be the point of contact for the manufacturing facility’s security. For instance, if a manufacturing facility has video surveillance with remote monitoring, the employee will be the contact for monitoring operators to reach out to whenever they need to report something.

The contact is also responsible for making sure new workers receive security training and keeping records of employees undergoing security training at least once a year. The point of this role is to assign ownership of security-related roles and tasks to one person. That person can delegate. The security plan should also outline the steps of designating backups in case the main contact is not out of the office.

4. Add multiple layers of security

It’s important to treat security as an ongoing program instead of as a one-and-done project. As stated before, security processes and technologies continuously advance. Manufacturing facilities don’t want to be using outdated technology that no longer does the job.

Not only does a manufacturing facility want to have the right security technologies but also multiple layers. The more layers you have, the less likely the manufacturing facility and its surroundings including the parking lot are at risk for theft, trespassing, and vandalism.

All too often, security for parking lots and garages is an afterthought. Many criminal acts occur in the parking area because it has fewer people around and many opportunities for wrongdoing including smash-and-grabs and catalytic converter thefts.

Other parts of the property that need layered security are entrances and exits. The more entrances and exits in a building, the harder it will be to protect it. The security professional should help limit the number of entry and exit points while verifying they’re properly lit and monitored by security cameras.

5. Use video surveillance with remote monitoring

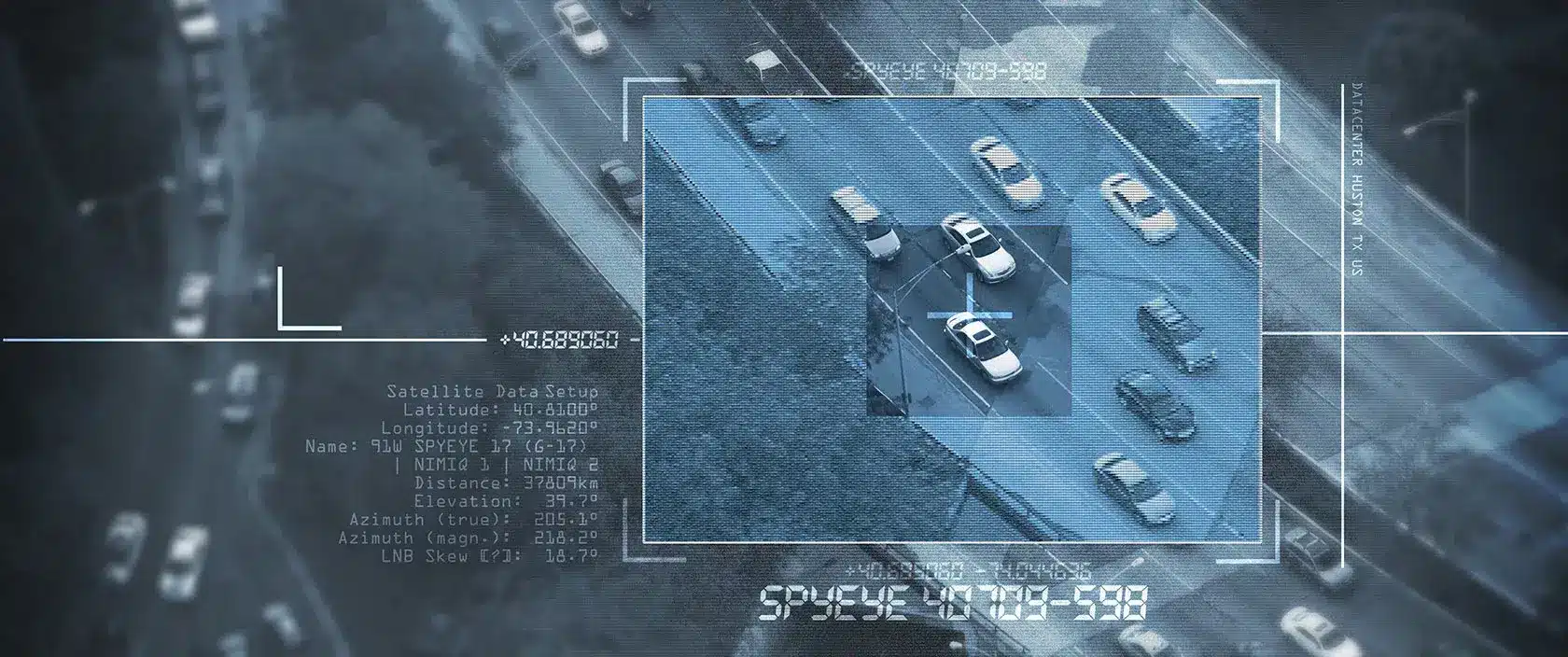

Remote video surveillance has the ability to multitask and add multiple layers to a manufacturing facility’s security. Security cameras with human and analytics monitoring can help deter crime, lower liability, and increase operational efficiency.

The sight of security cameras can act as a deterrent. The human monitoring operator can also utilize an onsite warning speaker at the facility to communicate with any intruders without being physically present. This is another layer. Remote video surveillance does more than put eyes on the perimeter inside and outside the manufacturing facility.

Video surveillance that incorporates video analytics helps reduce the trained monitoring operator’s workload. The two working in conjunction can also help catch potential crime before damage happens and potential safety problems before anyone gets hurt. The system can save and store all video recordings for use as evidence or in training.

6. Integrate an access control system

An effortless way to manage access and entry is with an access control system. It allows authorized people to enter the building while restricting access to areas or rooms in the facility, such as a data center room and parking garage. Unlike other automated entry systems, an access control system tracks who accesses any part of the manufacturing facility.

An access control system makes it effortless to grant and revoke access in real time. Whenever a worker resigns, it’s easy to revoke their access. An access control system can do more when it’s part of integrated security. It can work seamlessly with video surveillance.

7. Consider cybersecurity for physical security

The health and security of security technologies also need to be checked and updated regularly. For example, ask video surveillance and monitoring vendors about the security of their security cameras and the integration with services on IP networks. A video surveillance system with remote monitoring runs on software. Like any other software, it can encounter new vulnerabilities.

Security companies need to issue security patches. In the search for a security vendor, ask about their security processes and procedures as well as update their own systems when they find security holes.

As for cybersecurity, many companies think of cybersecurity as its own separate thing. But this kind of thinking is risky. Hackers may try to break into the manufacturing facility to access data. Security-forward companies view cybersecurity and physical security as part of a whole. This is why the convergence of physical and cybersecurity is important.

What’s Next?

In this era of constant change and evolving threats, the security of manufacturing plants is a multifaceted challenge that demands attention and innovation. The next step is to learn about security systems by picking up this free guide “Live Video Monitoring: More Than Just Catching Criminals” or contact us with your questions.

Texas Private Security License Number: B14187

California Alarm Operator License Number: ACO7876

Florida Alarm System Contractor I License Number: EF20001598

Tennessee Alarm Contracting Company License Number: 2294

Virginia Private Security Services Business License Number: 11-19499

Alabama Electronic Security License # 002116

Canada TSBC License: LEL0200704