In the current landscape of manufacturing, security remains a paramount concern as technology advances. The convergence of traditional manufacturing processes with current technologies like the Industrial Internet of Things (IIoT) and artificial intelligence has ushered in a new era of possibilities, but it has also brought forth unprecedented challenges in terms of cybersecurity.

As facilities become more interconnected and data-driven, the potential attack surface for cyber threats widens, demanding a proactive approach to safeguarding critical systems and sensitive information.

To navigate these evolving challenges, manufacturing enterprises are adopting advanced strategies to fortify their security posture. As the industry continues to innovate, the requirement to stay ahead of emerging threats remains a constant, propelling the manufacturing sector toward a more secure and resilient future. Here are the key trends and strategies for manufacturing security in 2024.

One notable trend shaping manufacturing security is the increasing reliance on interconnected devices and systems. While this connectivity enhances efficiency and real-time decision-making, it simultaneously exposes vulnerabilities that malicious actors may exploit.

As a result, there is a growing emphasis on implementing robust cybersecurity measures to protect against data breaches, unauthorized access, and other cyber threats. Manufacturers are recognizing the importance of adopting a holistic approach that encompasses both digital and physical security layers to fortify their operations.

Another significant trend is the integration of artificial intelligence (AI) and machine learning (ML) in manufacturing processes. These technologies offer substantial benefits, such as predictive maintenance and optimized production, but also introduce novel security concerns. The ability of AI algorithms to adapt and learn from data raises the stakes for ensuring the integrity and confidentiality of the information they rely on.

This includes investing in state-of-the-art cybersecurity tools, conducting regular risk assessments, and fostering a culture of security awareness among employees. Collaborative efforts between manufacturers, cybersecurity experts, and regulatory bodies are also on the rise to establish industry-wide standards and best practices, acknowledging that security is a collective responsibility in the dynamic landscape of modern manufacturing.

Applying the Zero-Trust Framework to Access Control

A noteworthy manufacturing security trend in 2024 is the adoption of a zero-trust framework for physical security. In the past, the traditional approach assumed trust. Zero-trust means treating every access request as a new one. Access is granted once the person or device has been verified.

Applying the Zero-Trust framework requires manufacturing facilities to change how they think about security. The premise is that every entity, whether a device or user, is viewed as untrusted until verified. This overcomes the challenges associated with conventional dependence on perimeter defense. Instead, facilities would conduct a more granular and dynamic evaluation of trust at every interaction point.

This means adopting encryption, multi-factor authentication, and continuous monitoring of network and physical traffic. Zero-trust consists of adding strict access control systems and doing a consistent review of access privileges.

This fortifies physical and cybersecurity while reducing the chances of insider threats and unauthorized access to critical systems and assets. For the zero-trust framework to succeed, all employees must undergo training to understand the importance of following security processes and learn how to spot potential risks.

Growing Use of AI

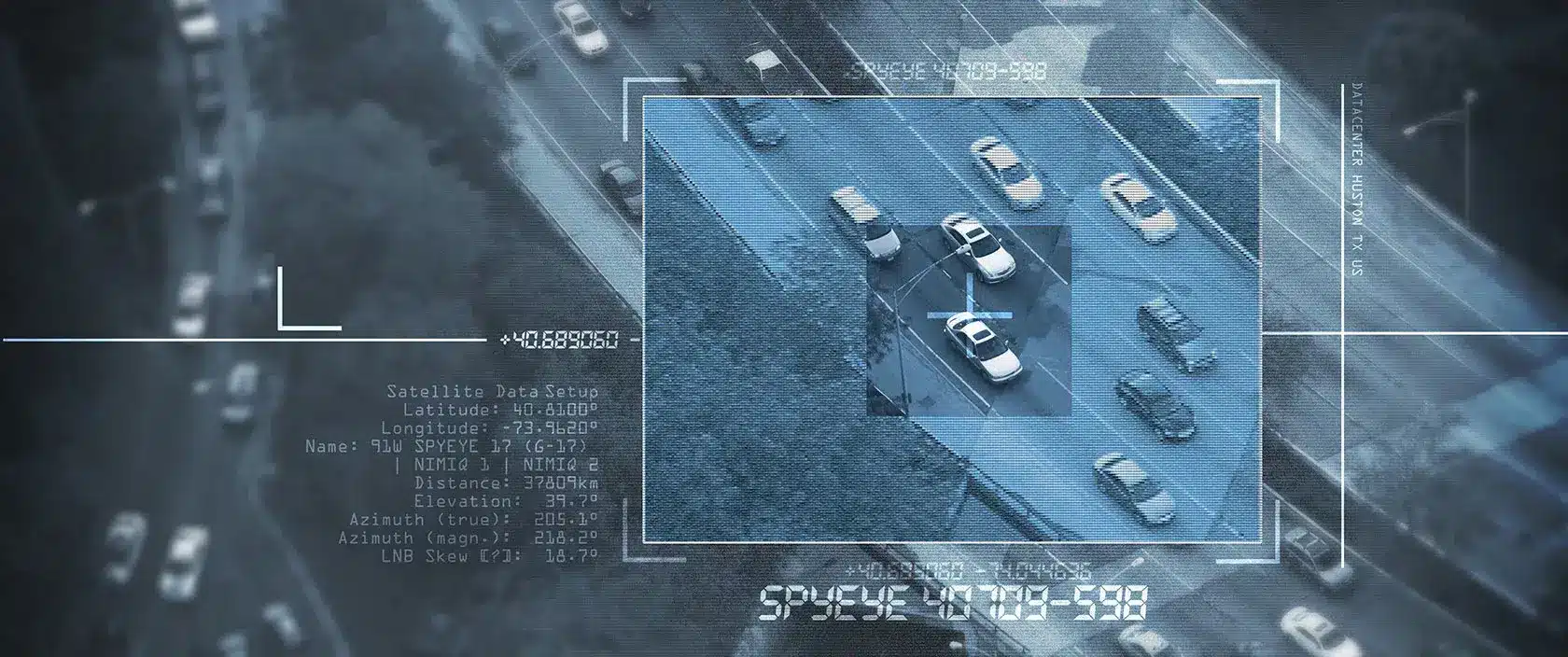

Artificial intelligence (AI) solutions are modernizing manufacturing security. The technology offers predictive analytics, automation capabilities, and advanced threat detection. With the massive amounts of data streaming in from remote video surveillance, and the Internet of Things (IoT), it becomes overwhelming and unmanageable without some AI to help make sense of it.

This is where machine learning algorithms enter the picture as guardians of manufacturing facilities’ security infrastructure. In addition to routine surveillance, these algorithms come with the ability to decode patterns, foresee potential threats, and find anomalies that might escape human inspection.

The genius of combining technology like AI and humans is the ability to convert predictions into proactive video cameras with remote monitoring strategies. Security teams armed with AI-generated insights can proactively tackle security gaps to help mitigate risks before they lead to actual crimes and breaches. This powerhouse reinforces security to help protect the facility, employees, vendors, and customers. They can also enhance operational efficiencies.

AI and automation encompassing predictive analytics in video surveillance take a proactive approach to manufacturing security. The capability exceeds traditional manufacturing security and access methods that were reactive. The convergence of integrated AI, automation, access control systems, and video surveillance elevates access methods as well as turns security measures that are formidable and more convenient.

Biometrics and Access Control

Fingerprint scans, facial recognition, and behavioral biometrics can now predict security breaches, identify unusual activities, and spot potential safety dangers. The addition of AI and automation in access control systems creates a seamless process for managing authorization. This is especially the case with multimodal biometrics.

Multimodal biometrics combines identifiers such as voice recognition, retinal scans, and behavioral biometrics. The synthesis of multiple biometric modalities promises to be more accurate while adding a layer of security in the manufacturing access control process for verifying identities.

Before this capability came along, single-layer authentication was easy to hack. Criminals found creative solutions to gain unauthorized access. The use of multimodal biometrics turns the authentication process into a multi-faceted one that helps bolster manufacturing security. Some systems relied on two-factor authentication, but it was very inconvenient for users who might have worked around it.

The value of this trend is that it applies user-centric thinking by prioritizing security and convenience. Employees experience less friction when working through the authentication process and entering secured areas.

The convergence of biometric and access control shows the industry’s commitment to staying ahead of emerging threats while implementing holistic solutions to bolster manufacturing security in 2024.

Convergence of Physical Security and Digital Security

For the past couple of years, there have been rumblings about the need to converge physical and digital security. That’s no longer something to ignore. Companies that focus on the convergence of physical and digital security can benefit from an effective manufacturing integrated security solution. Advancements have improved the seamless integration of the two securities as they become a more interconnected and interdependent security infrastructure.

The addressing of physical security and cyber threats cannot be siloed. They cross paths as they affect one another. Therefore, fighting back requires joining the two security functions. In doing so, manufacturing facilities can reinforce their security stance with robust measures that do more than protect digital and physical assets. Convergence helps protect the giant pools of sensitive data that underpin modern manufacturing security systems.

Manufacturing security must fuse physical and digital security to take a holistic approach. As a result, it allows their security teams to be aware of and focus on the interdependence of these two security branches. Embracing digital security as a vital part of physical security and vice versa helps ensure manufacturing is proactively ready to address the complexity of the always-changing digital age.

Sustainability and Environmental Security Solutions

The growing emphasis on environmental security and sustainability will continue in 2024. This shift necessitates looking at how facilities can protect their physical spaces while supporting environmental, social, and governance (ESG) goals. The convergence of environmental goals and security is a strategic reaction to cultivate sustainable practices.

To maintain the safety and well-being of employees and assets, manufacturing is investing in environmental sensors. These monitor temperature, air quality, and humidity to provide real-time data.

The current information ensures leadership addresses any problems early on before they become a bigger problem. The use of environmental sensors is a proactive approach to monitoring and mitigating potential environmental threats that could endanger security and ecological well-being.

Supply Chain and Geopolitical Uncertainty

The manufacturing industry is vulnerable to geopolitical conflicts that may impact the manufacturing, transportation, and distribution of products. The supply chain can be susceptible to political instability and trade tensions. Therefore, the supply chain crisis and geopolitical uncertainties largely affect manufacturing security.

These trends won’t change in 2024. Manufacturing companies that collaborate with government agencies, industry associations, and security partners will have a better chance of navigating these thorny geopolitical landscapes.

Applying Manufacturing Security Trends in 2024

These manufacturing security trends help facilities be more proactive in confronting advancing threats. At the same time, they’re more user-friendly while remaining environmentally conscious. The value of incorporating these trends is the fortification of manufacturing security while creating a safer, more resilient, and sustainable business environment.

Moreover, manufacturers need to collaborate closely with reliable security allies and subject matter experts. Together, they should develop and implement strong security solutions tailored to the manufacturing industry’s unique risks and requirements.

Remote video monitoring stands as a pivotal technology that can help enhance security measures within manufacturing facilities. This sophisticated surveillance system allows for real-time observation of the premises, enabling security personnel to monitor activities from multiple angles at the same time.

The integration of advanced video analytics and human intelligence further empowers the system to help identify unauthorized access or suspicious behavior instantaneously. This immediate detection capability is crucial in deterring potential theft, vandalism, or safety incidents, ensuring that swift action can be taken to mitigate risks.

These partnerships can help manufacturing facilities remain resilient, ensure the integrity of their operations, and protect their competitive standing in a world that is progressively intricate and interlinked.

Reach your 2024 manufacturing physical security goals by checking out this guide on Security Systems 101. For the latest manufacturing security solutions that can help meet your requirements and yield a fast ROI, contact us.

Texas Private Security License Number: B14187

California Alarm Operator License Number: ACO7876

Florida Alarm System Contractor I License Number: EF20001598

Tennessee Alarm Contracting Company License Number: 2294

Virginia Private Security Services Business License Number: 11-19499

Alabama Electronic Security License # 002116

Canada TSBC License: LEL0200704