In a dynamic waste management and recycling industry, achieving efficient and compliant operations is a top priority. Enterprise Resource Planning (ERP) guidelines offer a robust framework for streamlining and optimizing these critical processes. However, embracing innovative solutions can elevate recycling operations to new heights within the ERP framework. By integrating cutting-edge camera monitoring and video review services, organizations can unlock a wealth of benefits, including enhanced compliance adherence, improved operational efficiencies, and a heightened overall effectiveness that propels their recycling endeavors to new levels of excellence.

The Role of ERP in Recycling Operations

ERP systems streamline and integrate various business processes by providing a centralized platform for data management. In recycling operations, ERP systems help manage inventory, track waste streams, ensure regulatory compliance, and optimize resource allocation. These systems facilitate real-time data collection and reporting, enabling better decision-making and operational efficiency.

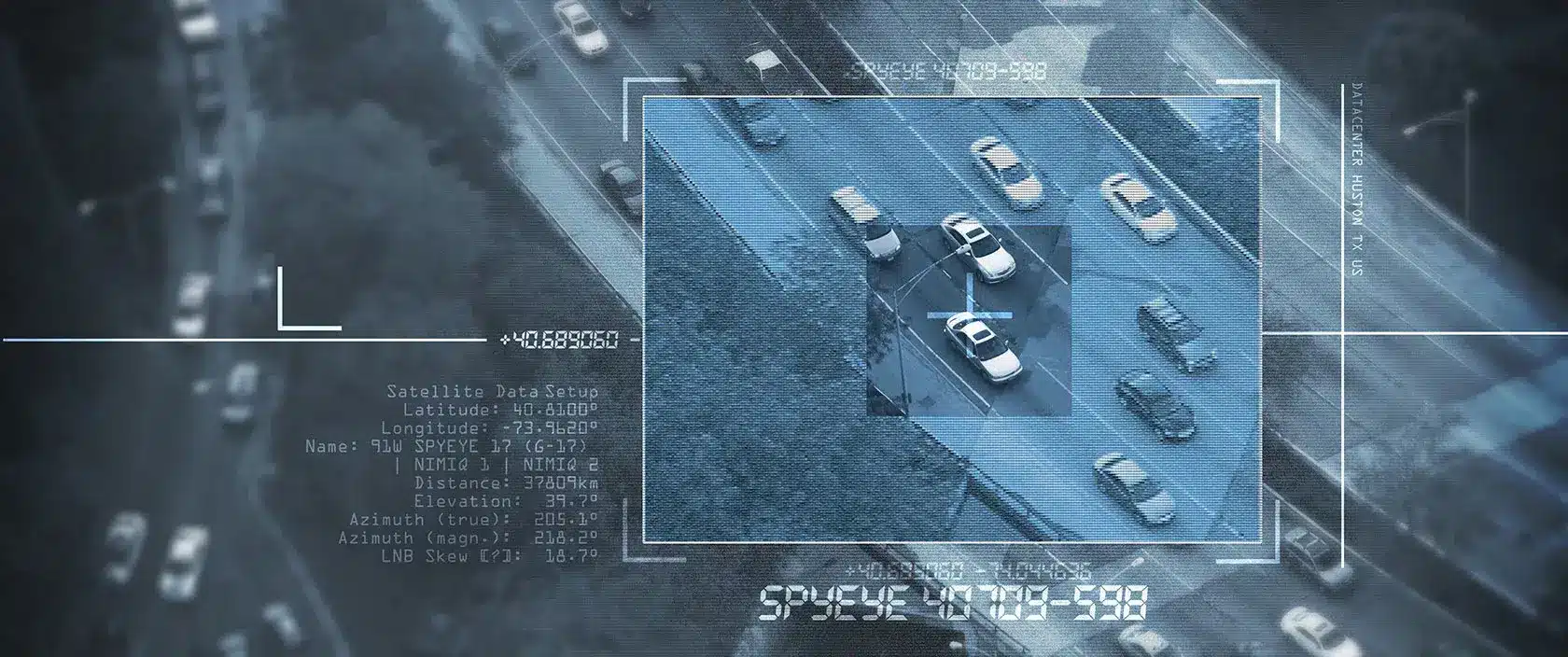

Integrating Camera Monitoring and Video Review Services

Video monitoring and review services can offer substantial support to the recycling industry, particularly in enhancing operational efficiency and expediting audits through various technological innovations. When integrated with ERP systems, these services provide critical insights into compliance, operational efficiency, quality control, and inventory management.

Enhanced Compliance and Reporting

Regulatory Compliance: Camera monitoring ensures that recycling processes adhere to environmental regulations and industry standards. Real-time footage can verify compliance with waste sorting, handling, and disposal regulations.

Audit Trail: Video records create a transparent audit trail, invaluable during regulatory inspections or audits, ensuring all operations are verifiable and in line with ERP guidelines.

Operational Efficiency

Process Optimization: Video review can identify bottlenecks and inefficiencies in the recycling process. By analyzing footage, managers can pinpoint areas for improvement, such as optimizing sorting lines or enhancing equipment usage.

Training and Safety: Monitoring footage can be used for training purposes, helping employees understand and follow best practices. It also enhances safety by identifying hazardous behaviors or conditions that need to be addressed.

Quality Control

Waste Sorting Accuracy: Camera systems monitor the accuracy of waste sorting, ensuring recyclable materials are correctly separated from non-recyclables. This improves the quality of the output and reduces contamination rates.

Maintenance and Downtime Reduction: By continuously monitoring equipment, cameras can help detect early signs of wear and tear, allowing for timely maintenance and reducing unexpected downtime.

Inventory Management

Real-Time Tracking: Cameras provide real-time visuals of inventory levels, helping managers make informed decisions about resource allocation and procurement. This ensures recycling operations are always equipped with necessary materials and equipment.

Loss Prevention: Monitoring systems help prevent theft or misplacement of valuable recyclable materials, ensuring inventory is accurately accounted for within the ERP system.

Implementing Camera Monitoring and Video Review Services

To effectively integrate live video monitoring surveillance and video review services with ERP systems, consider the following steps:

- Assess Requirements: Evaluate the specific needs of your recycling operation, including the number of cameras required, key monitoring areas, and desired outcomes.

- Choose the Right Technology: Select high-quality cameras and video review software that can integrate seamlessly with your existing ERP system. Ensure the technology supports features like high-definition video, real-time alerts, and advanced analytics.

- Installation and Integration: Install cameras in strategic locations, such as sorting lines, processing areas, and inventory storage. Integrate the video feed with your ERP system to ensure data from both sources can be analyzed together.

- Training and Implementation: Train staff on using the new technology effectively. Ensure they understand how to access and interpret video data and how it integrates with the ERP system for improved decision-making.

- Continuous Monitoring and Improvement: Regularly review video footage and ERP data to identify trends, issues, and opportunities for improvement. Use this information to continuously refine and optimize recycling operations.

Advanced Technologies in Video Monitoring

Material Sorting Accuracy

High-resolution and hyperspectral cameras capture detailed information on material types, crucial for effective recycling operations. These cameras operate in challenging conditions, such as low-light environments, where thermal cameras can detect heat signatures, maintaining continuous surveillance.

AI and Autonomous Systems

AI-driven and analytics-based systems enhance video monitoring capabilities by autonomously identifying and categorizing materials based on their characteristics, reducing reliance on human sorting. AI algorithms recognize subtle differences in materials, improving the purity and overall value of sorted recyclables.

Anomaly Detection

AI systems monitor for irregularities, such as foreign objects in recycling lines or unauthorized access, enhancing both security and operational efficiency.

Predictive Analytics

Predictive analytics transform operations within the recycling sector by analyzing vast datasets to forecast potential inefficiencies or safety hazards. Facilities can proactively address issues before they escalate, optimizing material recovery and ensuring equipment longevity through preemptive maintenance.

Compliance and Regulatory Requirements

Camera monitoring systems provide real-time visual data that can be automatically logged and analyzed, ensuring recycling operations consistently comply with local, national, and international regulations. Real-time monitoring allows immediate detection and correction of non-compliant materials, reducing the risk of regulatory fines and shutdowns. Video review services provide a documented history of compliance efforts, crucial during audits and inspections, building trust with regulatory bodies and stakeholders.

Operational Efficiency

ERP systems streamline various processes within a recycling facility, such as scheduling, resource allocation, and workflow management. When combined with camera monitoring, these systems further enhance efficiency by providing visual insights that support data-driven decision-making. Cameras can monitor the flow of materials through the recycling process, identifying bottlenecks or inefficiencies not apparent through data alone. Reviewing video footage allows managers to identify patterns and implement process improvements, increasing throughput and reducing downtime.

Quality Control

Quality control is crucial in recycling operations to ensure final products meet industry standards and customer expectations. Camera monitoring systems allow for continuous inspection of materials as they move through the recycling process. Integrating these visual systems with ERP software provides a comprehensive quality control framework. If a camera detects contaminants or improperly sorted materials, the ERP system can flag these issues and trigger corrective actions, ensuring only high-quality materials proceed through the recycling process.

Inventory Management

Effective inventory management is essential for the profitability and sustainability of recycling facilities. Camera monitoring systems provide real-time visibility into inventory levels, reducing the likelihood of shortages or overstock situations. When integrated with ERP systems, this visibility is enhanced, offering more accurate and timely inventory data. Cameras monitor stockpiles of recyclable materials and finished products, providing visual confirmation of inventory counts recorded in the ERP system. Improved inventory management leads to better resource utilization and cost savings.

Ultimately, in the landscape of the ever-evolving recycling industry, where efficiency and compliance are paramount, organizations must continually seek innovative solutions to propel their operations forward. The integration of cutting-edge camera monitoring and video review services with robust Enterprise Resource Planning (ERP) systems presents recycling facilities with a powerful synergy of tools. This strategic combination enables facilities to elevate their operations, foster enhanced compliance adherence, optimize operational efficiencies, and fortify quality control and inventory management practices.

As the demands for sustainable practices and regulatory compliance continue to intensify, such integrations will prove pivotal in driving innovation and excellence within the sector. Recycling facilities that embrace this synergistic approach will position themselves at the vanguard of industry innovation, contributing significantly to a more sustainable future for all stakeholders.

In an era where environmental stewardship and responsible resource management are increasingly critical, the fusion of advanced monitoring technologies and comprehensive ERP frameworks empowers recycling facilities to lead the charge, setting new benchmarks for operational excellence and environmental responsibility.

To learn more about Stealth Monitoring’s live video monitoring and surveillance and how it can help you achieve compliance and avoid fines, contact a scrap and recycling security specialist today.

Texas Private Security License Number: B14187

California Alarm Operator License Number: ACO7876

Florida Alarm System Contractor I License Number: EF20001598

Tennessee Alarm Contracting Company License Number: 2294

Virginia Private Security Services Business License Number: 11-19499

Alabama Electronic Security License # 002116

Canada TSBC License: LEL0200704